Diving Into Remote Site Energy Use

Situational Breakdown

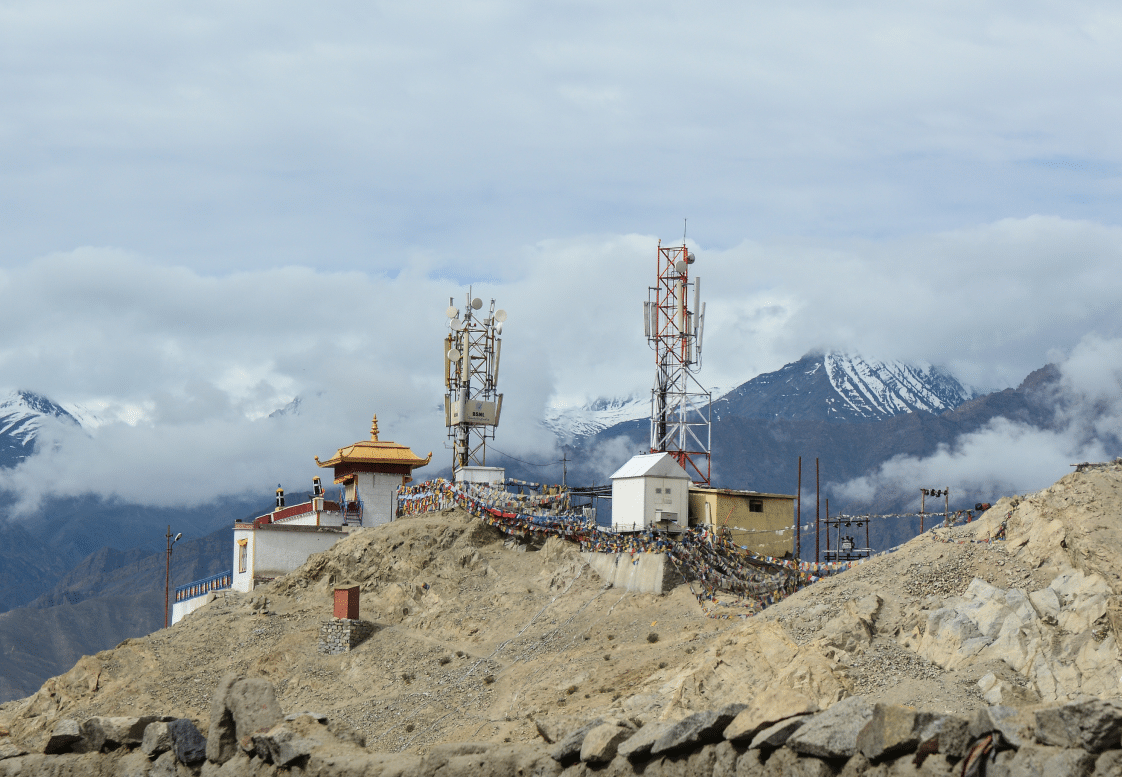

Telecommunications services and coverage have been making great headway across the African continent. In Nigeria alone, the number of 3G and 4G towers has jumped by more than 73% to 53,460. As we have discussed both in our blog and in many previous experiences with clients in the region, there are several common issues encountered here that we have found effective solutions for.

Keeping track of hundreds or thousands of remote sites and assets is exhausting without remote access and management capabilities. Moreover, it is nearly impossible without such a remote monitoring and management tool to understand the source of any malfunctions, let alone mitigate issues without being on-site.

This is especially true in terms of energy consumption and understanding why certain sites or energy assets are performing improperly. Whether it is fuel usage, improper voltage and operating loads, or simply an overreliance on certain assets due to local instability, these issues need to be diagnosed and stakeholders notified in real-time.

The Client’s Pain Points

Nigeria has struggled for years with vandalism and theft issues relating to energy assets like fuel and backup batteries from telecom base stations. As they have worked to expand and stabilize coverage countrywide, these “singular” events cause a ripple effect that can cause sweeping outages.

Galooli’s remote monitoring and management (RMM) solution helped dive deeper into the challenges our client faced. Even without wanton acts of destruction, the region itself struggles with a lack of electrical grid availability. In addition, fuel theft has been a consistent nuisance to efficient operations, and the client had little idea when generators were in use, when the grid was available, and how much fuel they were using.

They also lacked visibility for these remote sites and the on-site energy assets. This meant the client had no idea if generators were operating at optimal levels or performance fixes were needed. They also had no idea when the grid was functioning and when outages occurred. Considering that these generators are the primary source of energy for these sites, this can cause costly extended downtime until they can be brought back online.

This is how we solved it

Galooli’s RMM was able to track and detect all these metrics and

provide these insights into the operations of our client’s remote assets. Our solution provided overarching visibility and live updates for these remote energy assets and facilities regardless of their orientation or location.

We were able to track the specific performance of each energy asset on-site and alert the client in real time to any malfunctions or errant events that occurred. In this way, they were able to immediately respond to these events, even pre-emptively, to prevent further damage and minimize downtime.

In addition, we were able to track the usage of these assets, to understand better how these sites were functioning overall and where optimizations could be made. We used AI-assisted analytics to discern specific insights and actions clients can take to maximize their energy efficiency by tracking historical and live data.

Our solutions also provided regular reports on the status of firmware and any inconsistencies that arose while updating and syncing any out-of-date assets in a batch from the comfort of our interface. Whereas such updates traditionally took place on-site and require technicians, travel, and other incurred costs, our RMM solution can fix many of these issues remotely.

This could still be a time intensive task, but with Galooli’s Cut Through, syncing hundreds of remote sites to operate at optimal levels can be done in a few hours instead of a few weeks. In addition, by tracking several key generator performance metrics, we discovered the low operating loads could be causing the increased overall fuel consumption our client experienced during this period.

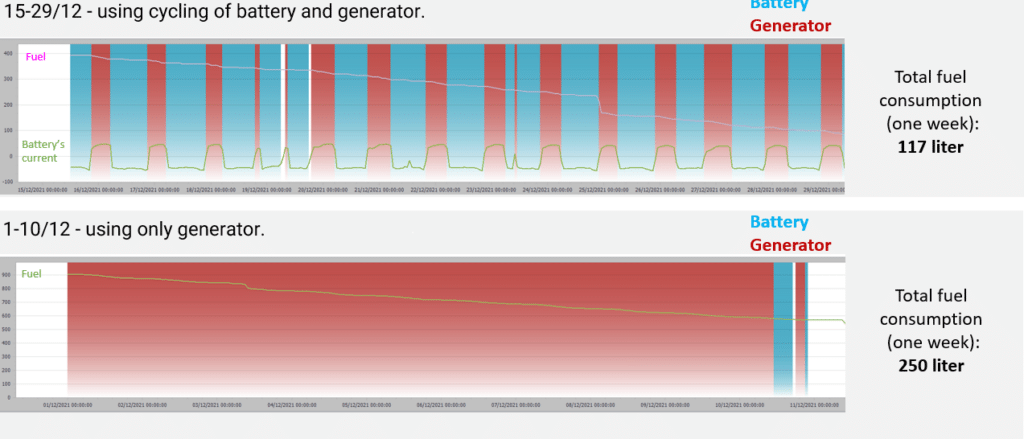

When examining their use of energy storage solutions, there was minimal use of and lack of upkeep for existing backup batteries. By replacing and installing these batteries, they can limit their reliance on fuel and generators used for backup power, reduce their carbon footprint, fuel usage, and maintenance costs.

Lastly, we introduced a comprehensive sustainability module that provides an in-depth look into an organization’s carbon footprint. This includes identifying problematic sites, separating scope 1 and 2 emissions, monitoring overall emissions, and tracking the emissions saved by using renewable energy sources like solar.

What Happened?

We implemented our solution at hundreds of sites across the entire Nigerian landmass in the calendar year 2021 alone. Due to this implementation, we were able to identify a litany of performance and efficiency issues present at the majority of the sites we monitored over this period. We found that the grid was available on average just over 30% of the time. This forced an overreliance on generators, and in the past month alone, the client saw a near 24% increase in fuel usage to 611,000 liters. With the insights gleaned from generator operations, the client saved 11% or over $500,000 in annual fuel costs from just several hundred sites out of a network of thousands. Integrating the full network would result in savings in the millions of dollars.

We also discovered that a number of the DG failure events could be mitigated by reconfiguring the generators to operate at proper thresholds. We found the root cause in the generators operating at extremely low loads between 31 and 38%, depending on site

grid usage.

Beyond causing strain on the machinery, this also led to frequent generator failures, around 1900 be exact. Moreover, we found that in the period of a single month, 38% of the sites experienced at least one extended outage.

These outages, and a great deal of the generator reliance can be mitigated for the majority of these sites. In fact, we found that weekly fuel use could be cut in half if a site used backup batteries effectively.

Lastly, there was a significant impact on the client’s carbon footprint. The increased fuel usage leads to greater greenhouse gas (GHG) emissions and is more damaging in general to the environment surrounding these sites. This means the client can now track the carbon footprint of each individual site and receive live alerts to excessive emissions.

The Client’s Pain Points

- Client faced frequent instances of vandalism and

theft of backup batteries, causing “ripples” of

outages - Grid availability was very spotty, but it was

unclear how often it was available and when the

outages occurred - Client had no visibility over their remote assets

and sites, having no idea the status of those sites

without physically arriving on-site - Client was unaware of any changes in their site

generators’ fuel use

Galooli’s Solution

- Implemented solution at hundreds of sites across

Nigeria - Client had full live visibility over their remote

assets and facilities - Grid availability was discovered to be extremely

spotty, on average only 30% of the time - Fuel use jumped by 24% to 611,000 liters

- Site generators were operating at 31 to 38% load, far below optimal levels

- There were 1900 generator outages identified in the monthly period alone

- 38% of the sites monitored experienced at least

one outage in just a single month - Over $500,000 in annual fuel costs saved from just several hundred sites

- Updating and properly using backup batteries could cut weekly fuel usage by more than half

About Galooli

Galooli is a pioneer in the green energy revolution.

The company is blazing a trail in energy management as a service with actionable insights into your operations.

Galooli’s remote monitoring solutions optimize energy usage, reduce operating expenditures and maximize alternative energy use.

Galooli provides a green and future-focused solution for multiple industries and use cases around the world, from metropolitan centers to the most remote installations.

Connect With Us

operational cost savings & efficiency?