With a global valuation expected to reach $4.7 by 2027, the telecom tower market is expanding rapidly to deliver service to over six billion people.

Network providers and site operators traditionally rely on periodic on-site maintenance to ensure optimal performance of these towers but struggle with high installation and operational and maintenance costs.

Yet, this ongoing maintenance is key to maximizing site efficiency and performance and reducing costs later down the line.

Let’s examine what tower maintenance means for telecom operators, how often you should check a tower, the types of towers, and how to effectively carry out maintenance reviews.

Why do you need to carry out regular maintenance?

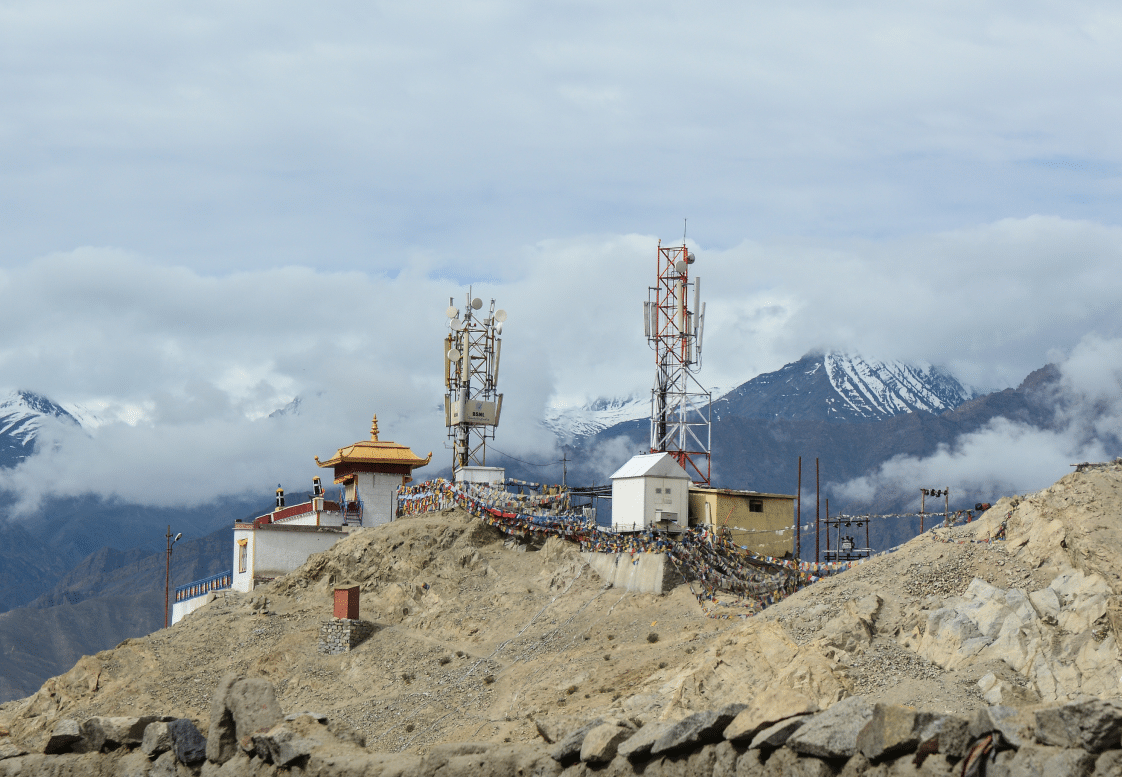

Telecom tower structures include communications equipment such as antennae, transceivers, a baseband receiver unit, a grid, batteries, and a generator.

Maintaining these components regularly ensures the successful transmission of data within the communications network. This is critical for a few reasons:

1. Ensures optimal performance

Network outages cost providers $260,000 an hour, with almost half of them taking over 24 hours to resolve.

And telecom operators have reported a 25% increase in outages over the past five years; that’s a lot of money spent on the same issues.

With energy costs hitting historic levels in some countries, regular maintenance checks that minimize outages — or prevent them altogether — are more crucial than ever.

By regularly maintaining tower structures, you can spot potential problems before they arise and cost hundreds of thousands.

2. Extends the longevity of equipment

Proper fuel management ensures that generators don’t go without fuel for long periods and prevents a need for widespread replacements.

Batteries stored in sub-optimal environments (the optimal setting is between 20°C/68°F to 25°C/77°F) negatively impact lifespan and performance. Regular maintenance checks ensure these optimal conditions exist to promote the long-term use of assets.

The telecom industry is subject to different compliance standards depending on the geographic region and regulatory body in charge. Without regulatory compliance, telecom companies can face hefty fines and even have their licenses revoked.

Checking and maintaining the equipment can extend its life while providing an opportunity to stay up-to-date with any compliance checks.

How often should a tower be checked?

This depends on the type of towers. Guyed towers require maintenance checks once every three years, whereas self-supporting towers are once every five years.

The Telecommunications Industry Association (TIA) requires towers to be more frequently maintained when:

- They threaten human life or property

- Reside in areas near the coast or other habitats that could cause corrosion to the towers

- Are in a location where theft is common

- Or in geographic locations of extreme weather conditions.

Always check guidelines relevant to your specific location, as these may differ.

How many types of telecom towers are there?

Telecom towers are essential to delivering continuous service to customers, often in large geographic regions. There are four basic types of telecom towers, each with advantages and disadvantages. Some are more suited to urban environments, while others require rural or suburban spaces.

1. Lattice / Self-supporting

Lattice or self-supporting towers are the most popular type of tower. Built on a solid foundation of triangular steel, they support long ranges, but the materials and construction for this type of tower are costly.

2. Guyed

Guyed towers are similar to self-supporting towers with cables in the ground (i.e., guy lines) for increased support in environments with windy or extreme weather conditions.

Although material requirements and costs are less than self-supporting towers, they require more space and can be unsuitable for large cities.

3. Monopole

As single-pole, self-supporting structures, monopole towers are one of the easiest towers to erect in populated areas.

They are also cost-effective but challenging to install due to increasingly strict zoning requirements.

4. Camouflage

Camouflage towers are towers whose appearance hides their design. These towers might look like trees, cacti, flag poles, church steeples, or water towers.

As demandsfor towers have increased, this type of tower has risen in popularity, particularly in scenic environments where a very tall structure would stand out.

What is tower maintenance, and how to carry it out successfully?

Tower maintenance includes a variety of tasks that ensure structures are safe, compliant with regulations, and perform specific tasks. Doing so extends asset lifelines, puts more money back into the company’s pockets and prevents frustrating outages.

The required tasks vary depending on the site, tower structure, and the company’s KPIs.

Some tasks could include:

Battery replacement: Backup batteries should be checked regularly to ensure optimal performance before a power outage.

In some geographic regions, battery theft is common, requiring on-site visits to replace them.

Attending critical inspection issues: Towers should always be inspected first from the ground to identify any safety issues or damages from machinery, lawnmowers, or vehicles.

Secure antenna and transmission lines, as well as any loose hardware.

Troubleshooting: Recurrent power outages, equipment malfunction, and poor generator performance are just a few issues that can require emergency maintenance visits.

Backup generator and HVAC maintenance: Backup generators should be checked regularly to ensure they are a reliable energy source during an outage.

In addition, HVAC operations should also be monitored and tracked to check the environment is conducive to optimal energy performance since they’re a significant source of energy waste.

How to carry out maintenance checks efficiently?

Regular maintenance of telecom towers traditionally requires on-site crews to arrive at the sites in remote locations. Too often, these on-site checks are periodic, making them insufficient for proper tower maintenance and optimizing energy usage.

Maintenance issues often arise in periodic checks that more frequent checks with remote monitoring could have prevented.

One way to overcome this is by utilizing remote energy monitoring solutions.

Remote monitoring allows for comprehensive monitoring of tower structures and assets – with real-time alerts to any issues. Remote monitoring can be a major game changer for those who often send many people to the rural site (taking time, resources, and money).

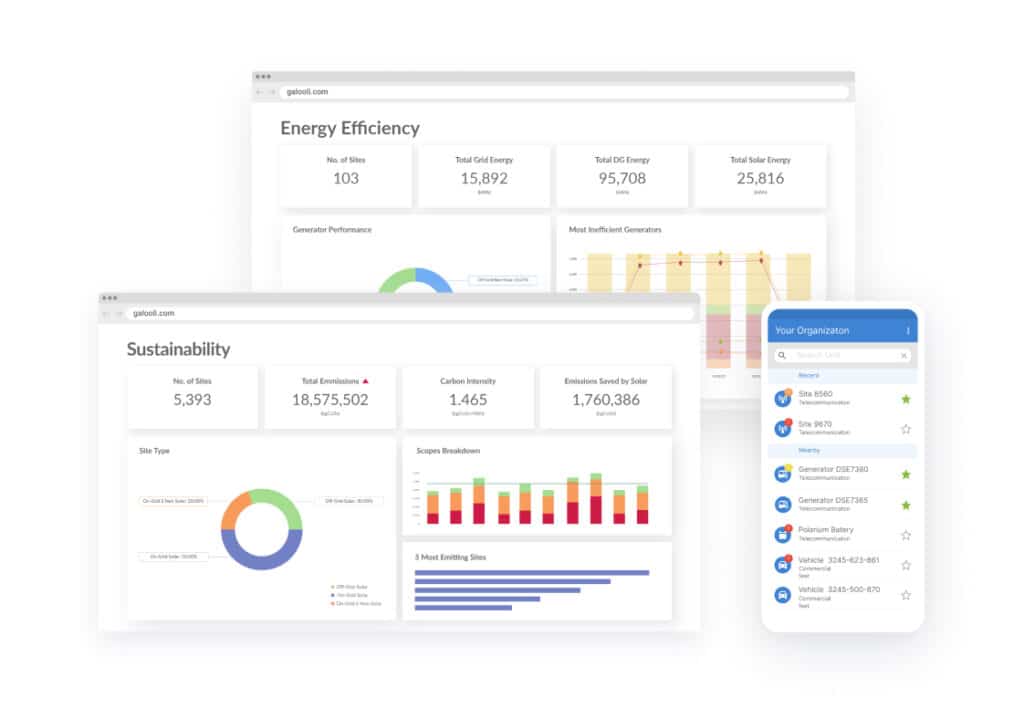

It allows telecom operators with hundreds or even thousands of sites in various locations to stay on top of these and gain complete visibility over energy assets.

Remote monitoring solutions provide:

- Predictive maintenance. Cloud and historical data from your facilities are collected and tracked to identify trends and anomalies that warn when a malfunction might occur or an outage is imminent. This drastically reduces the need for periodic on-site visits and replacement parts, extending the lifetime use of remote assets.

- Establishment of performance thresholds. Trends and anomalies in your data help identify ways to improve energy and operational efficiency. Key performance indicators (KPIs) track carbon emissions, asset health, HVAC operations, operations, capital costs, fuel usage, renewable energy utilization, and more.

- Greater transparency. Data and actionable insights related to fuel and alternative energy efficiency provide greater transparency, helping telecom sites to be more environmentally-conscious without sacrificing operational efficiency.

Galooli’s remote energy monitoring solution allows site operators to understand exactly where their assets are and their performance in real-time, gaining better insights into operational efficiency and maintenance requirements.

With Galooli, you’ll leverage remote monitoring to gain unprecedented data and insights into your operations to see whether or not you’re hitting your emissions goals, meeting regulatory requirements, and calculating savings from renewable energy sources. All without setting foot on your site.