Imagine a sensor that could tell you exactly how you use your energy for every powered device your organization controls. Receiving live updates and alerts of any events and performance data that can help maximize your energy efficiency and use. Devices that can help determine the contribution of your sites to your carbon footprint, and understand which are problematic.

These are all part of reality, as internet-connected devices and previously “dumb machinery” become able to provide actionable insights from their operations.

These devices are designed to track and retrieve countless KPIs, many unique for certain industries. In particular, some IIoT devices can be used to track various energy use and performance metrics for remote sites.

First, let’s briefly define exactly what “IIoT” is, and the difference between IoT and IIoT.

What is IIoT and how does it differ from IoT?

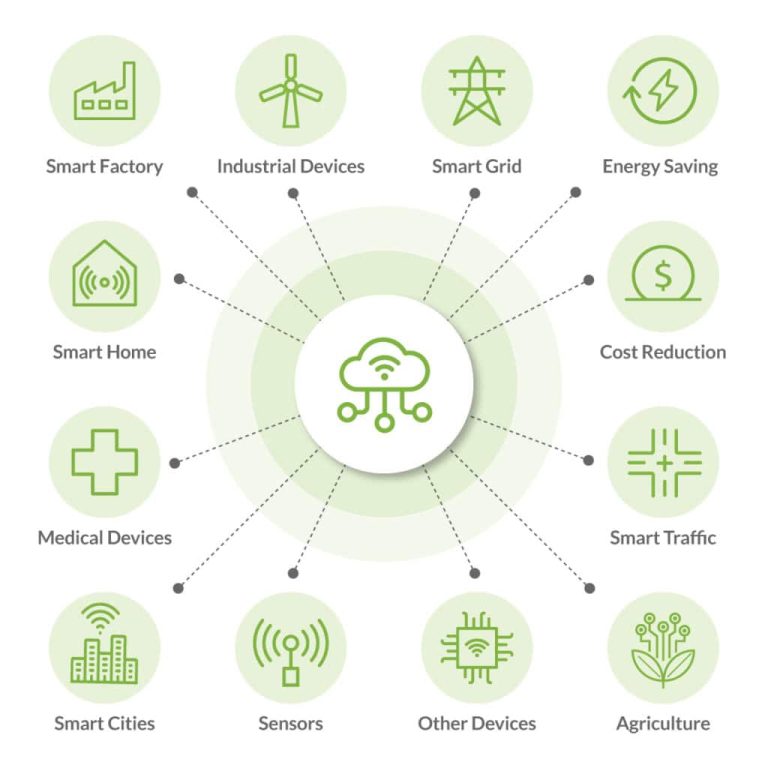

The Industrial Internet of Things (IIoT) is the application of and use of internet-connected smart devices within the realm of industrial sectors and uses. The primary objective of these devices is machine-to-machine connectivity, along with machine learning and big data analytics. They exist to reliably collect and share data from each one of these data nodes simultaneously.

IoT and IIoT are similar in ideation. However, besides an extra “I”, IIoT is focused on industrial, enterprise, and large-scale deployments, along with supply chain monitoring. IoT on the other hand is very consumer-centric, turning everyday devices into intelligent, remotely controlled smart gadgets like lights, speakers, and thermostats.

IIoT extends past everyday interactions with smart devices and creates a synergy of operational and information technology (OT and IT) in an enterprise setting. This provides greater opportunity for automation and optimization, as well as greater overall visibility of an organization’s supply chain and infrastructure.

So what are some of the benefits of implementing IIoT solutions in your operations, and how do they really improve your energy use and sustainability?

Benefits and importance of IIoT in energy optimization

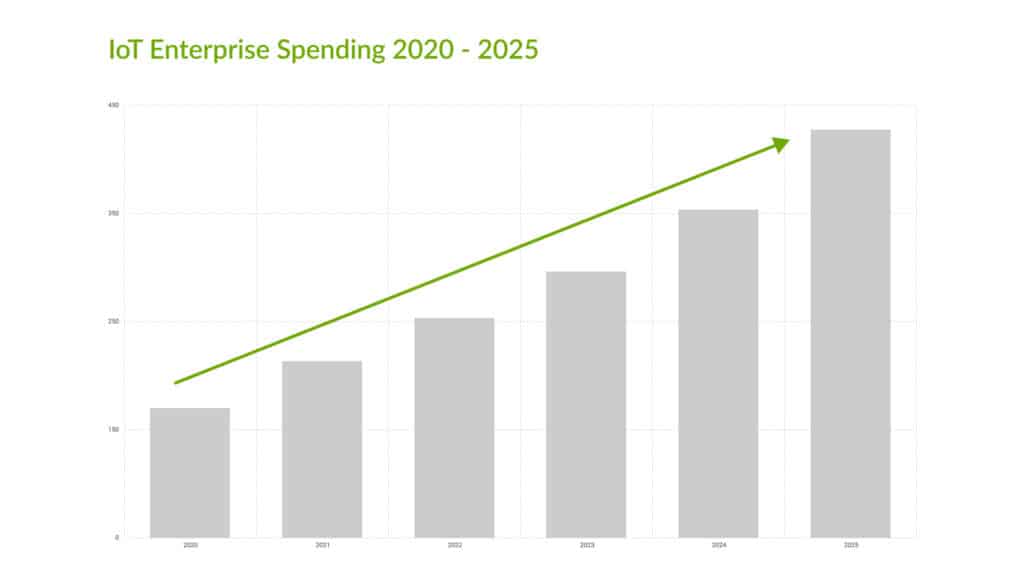

So IIoT has the potential to optimize industrial operations, but what is happening in the field itself? The IIoT industry is growing at an exponential rate, and IoT Enterprise spending will balloon from a little under $160 billion to nearly $412 billion in 2025.

IoT connections are also growing at an exponential rate, and are expected to surpass 25 billion devices by 2025. For Industrial IoT, that number is expected to be eight billion devices alone, with one billion located in the ICT sector.

The primary benefit of IIoT devices and solutions is maximizing the potential of data and KPIs collected from machines and smart assets. This is done to create and improve automation, improve decision making, and most importantly, increase energy efficiency.

Some of the other benefits include:

- Enhanced regulatory compliance

- Reduced maintenance costs and on-site visits

- Optimization of renewable energy asset use

- Reduction of Operational and Capital Expenditure (OPEX and CAPEX)

- Improving demand management

- Reduced carbon footprint and emissions

- Minimize energy costs and inefficiency

- Improve sustainability and asset longevity

- Create new revenue streams for customers and providers

Beyond these benefits, in the last year, IIoT solutions like ours helped boost labor effectiveness by 20 to 40% through KPI and performance indicator monitoring. At the same time, remote IIoT management tools like Galooli’s provided a 10 to 40% reduction in on-site maintenance costs.

Trials and tribulations of optimizing energy use with IIoT

Though the benefits are numerous, optimizing energy use for IIoT systems can be a complicated task. This is made even more convoluted by the variety of IoT systems used by one organization, and the lack of standardization in terms of software, hardware, compatibility, and security protocols.

Unreliable energy sources are a major factor in ensuring continuity is maintained, especially if certain sensors or devices rely on limited power sources like batteries. Efficiently powering or optimizing energy use for several dozen different devices is difficult; when they number in the thousands, millions, or billions, it is a massive undertaking.

Another challenge is efficiently installing the physical arrays of sensors at sites that can be incredibly remote and inaccessible. Though this problem may be alleviated by these sensors, the effort to install them can be an obstacle to adoption.

Finally, implementing a network of devices all collecting, transferring and communicating with centralized data centers takes up a great deal of network bandwidth. The network capacity of some organizations may not be able to support the additional strain.

Introducing edge data centers is one possible solution to this issue, but not all organizations can afford to set up multiple satellite sites to improve efficiency.

Now that we’ve established the benefits and challenges relating to IIoT, let’s get into how these solutions can be implemented at different levels of your operations.

How are IIoT organizations changing the way they use energy

B2B organizations like ICT providers are implementing IIoT energy management solutions in a number of different use cases. One case is in car fleets, where IIoT sensors and devices are used to track and manage vehicle and driver performance, as well as any potential problems or events that are out of the ordinary. This can provide valuable insights into how organizations with fleets of vehicles and maximize their efficient use and minimize wasted fuel.

In the same vein, organizations in manufacturing and Industry 4.0 overall are an intrinsic part of this landscape. Countless machines, conveyors, automated and manually controlled devices, all need to be actively monitored and managed remotely. This area has countless use cases and implementations for IIoT to maximize productivity, minimize wasted energy, and learn peak and trough times to promote efficient use and production of energy and goods.

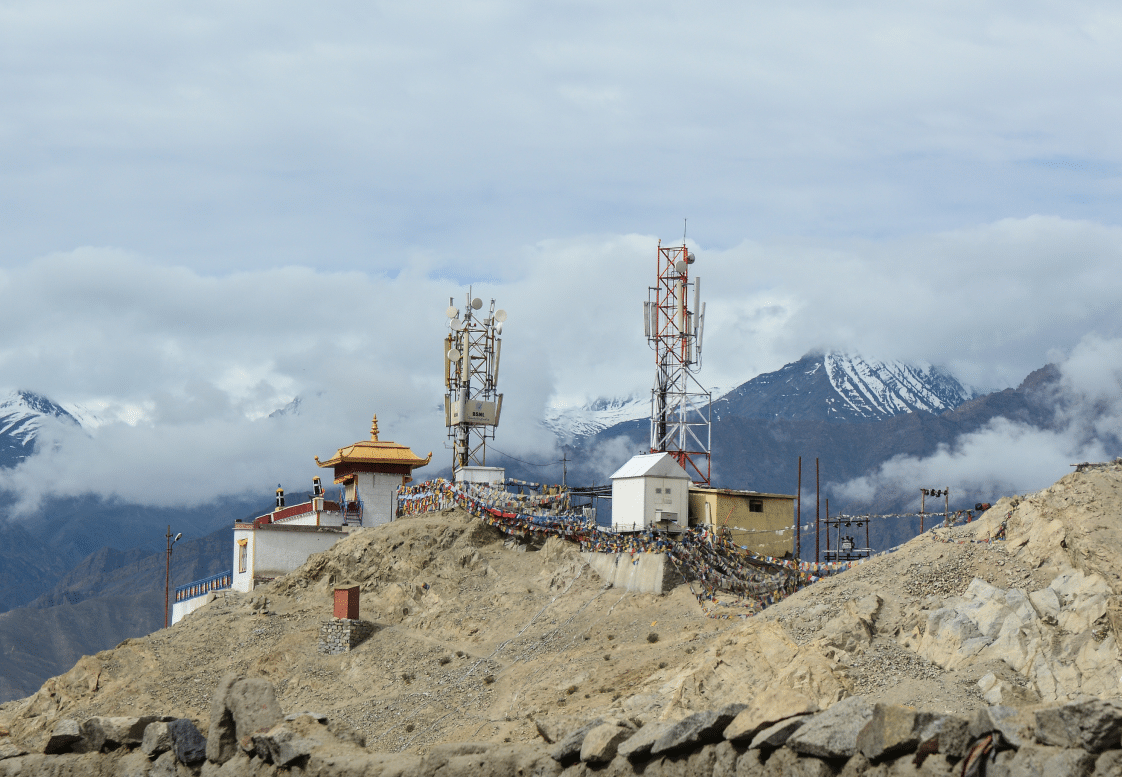

When it comes to telecom, networks, and other service providers, organizations are responsible for maintaining and keeping track of hundreds, if not thousands, and tens of thousands of remote sites. These locations, depending on the area, can be extremely remote and difficult to reach if a problem ever arises.

For this reason, IIoT solutions can help to keep track of the performance of the various connected or potentially connected assets onsite. They can also maximize your energy efficiency by detecting fuel and battery theft, fuel waste, and lack of optimization when it comes to energy use and renewable energy sources.

So how is Galooli going about changing this landscape?

Galooli – Smart energy management solutions for Telcos, Industry 4.0 and beyond

Galooli’s remote monitoring and management solution (RMM) IIoT solution offers agnostic compatibility that is adaptable to each organization’s unique situation. We can interface with existing infrastructure and sensors, along with integrating our own sensors or with the cloud ecosystem for a variety of energy assets.

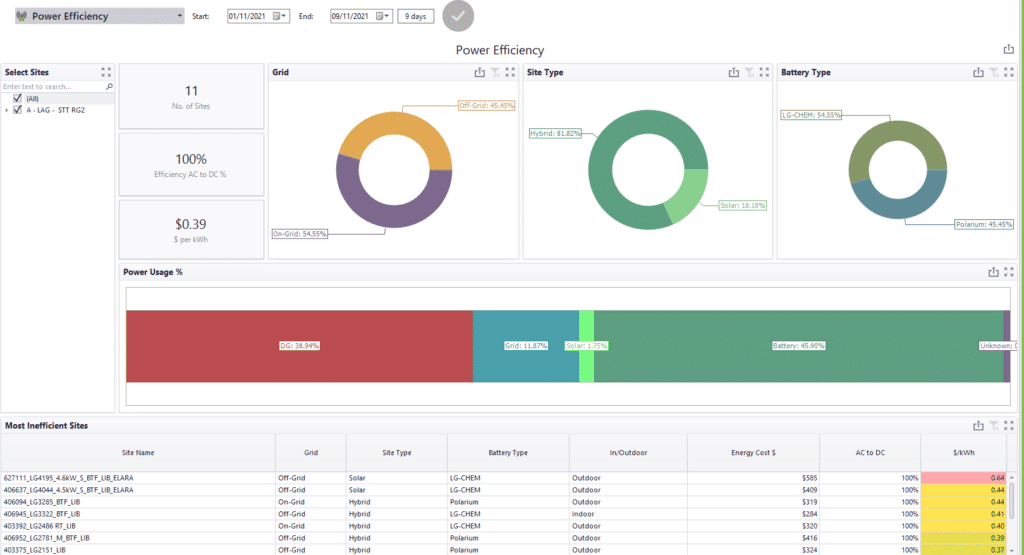

You might still be asking, what does this have to do with energy optimization? It all begins with beginning to monitor and manage energy assets you have on-site or in fleet form. This includes understanding how your energy is being used, and which energy assets are relied upon more.

Most importantly, our RMM solution shows which of these energy sources is running efficiently, and which can be optimized. This includes carbon emissions both Scope 1 and Scope 2, on an organizational and per-site level.

Oftentimes this comes in the form of telecom sites where solar panels are installed but are used improperly and existing sunlight is taken advantage of poorly. Galooli provides insight into when these assets should be relied on, saving fuel and reliance on backup batteries in the case of a power outage. We also keep track of any outlying performance issues or potential equipment malfunctions that can cause energy problems, as well as overreliance on certain energy sources as opposed to others.

In terms of fleets, we help fleet operators track vehicle and driver behavior and position during work hours. This provides live updates of any errant events like accidents, malfunction, sudden stops, speeding, reckless driving, or even excessive idling. This also includes examining fuel usage and detecting any potential irregularities like theft or maintenance issues.

Our RMM solution also provides dynamic and agnostic energy management for a variety of industrial applications, and more are being added every day.

Connect With Us

operational cost savings & efficiency?