Has your organization ever dealt with service outages due to energy issues?

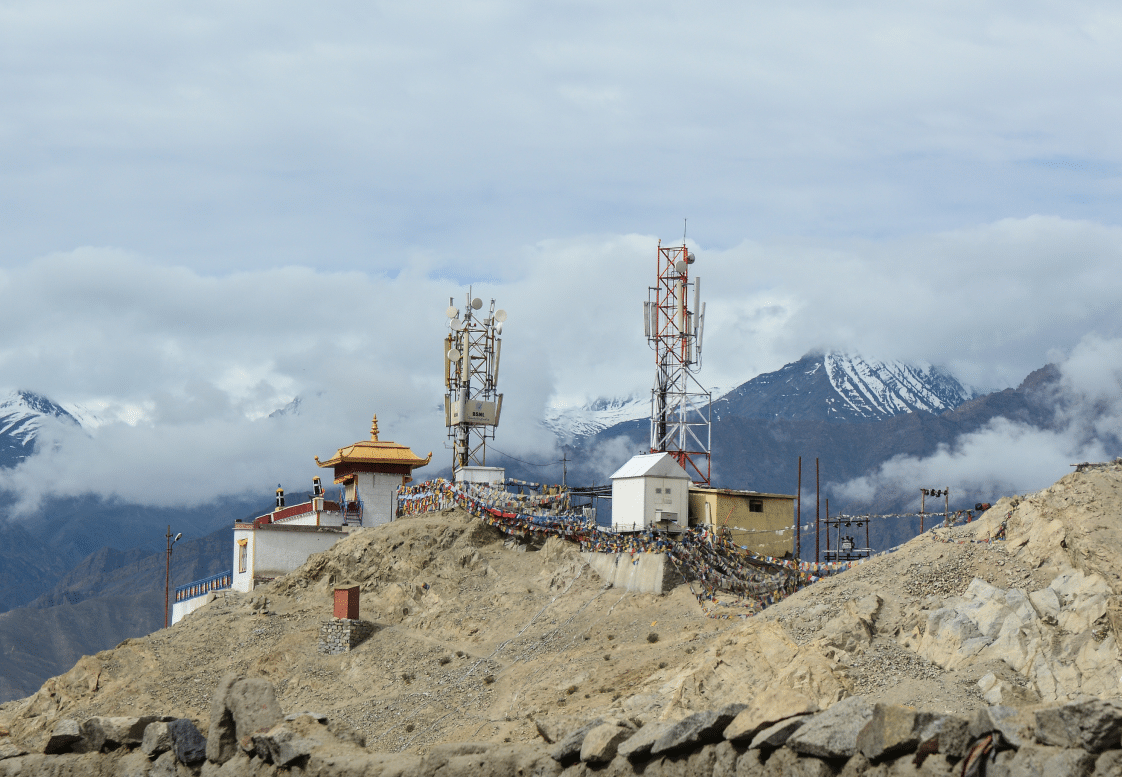

If you are an Information and Communication Technology (ICT) enterprise or site operator, chances are this is a problem you’ve come across, or maybe dealing with this very second. Just look at India – 60% of the telecom sites in the region suffer from grid outages up to 8 hours a day.

For this exact reason, backup power supplies like generators are critical energy assets to have on-site for every organization. This is especially true for those with remote and sensitive network and computer infrastructure relying on a continuous power supply to operate effectively.

The market is booming and expected to reach $30 billion by 2027, pointing to a rapidly increasing need for these energy assets. This also means remote monitoring and management solutions capable of providing insights and visibility for these assets are more important than ever.

Before we go any further, let’s talk briefly about several of the more prominent types of generators for B2B and industrial applications.

Generator Breakdown - Which is which?

Generators come in all shapes and sizes, from portable generators and single-household backups to those that can support a large facility, remote site, or data center. For our purposes, we will be focusing on two primary types of generators deployed in industrial use cases, diesel and hybrid generators.

Diesel Generators

Diesel generators, or “DG” are the most common generator we think of when it comes to backup power supplies for telecom sites and other industrial facilities. They rely on diesel fuel to provide power when grid or other energy assets are unavailable. They are used and known for their reliability, especially the longevity of the engine, consistent performance, and relatively low overhead for the generators themselves.

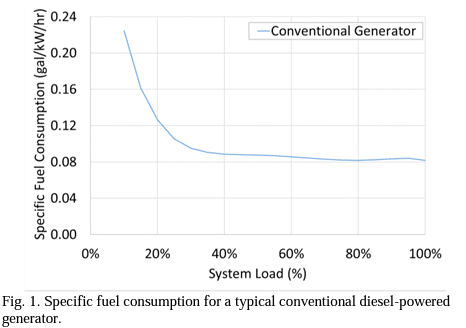

However, fuel costs are rising globally, and one of the biggest drawbacks to diesel generators is their fuel consumption when it maintains lower system loads (under 40%). From that point, the rate of fuel consumption stays more or less stable up to its full load capacity.

As many generators are chosen by peak load capabilities, oftentimes a remote site is left with a generator that is too large or small for their needs. This leads to improper system load, wasteful fuel use, and lower lifespans for the generators themselves. They also require fossil fuels to operate, producing a significant amount of carbon emissions from their operations.

Hybrid Generators

Hybrid generators are any of a range of diesel generators that also includes additional energy sources included to improve their operations and efficiency. They include energy assets such as backup batteries and renewable energy sources including solar and wind.

Using these two technologies together, hybrid generators are able to rely on these alternative energy sources as much as possible, reserving diesel generator operations for the last resort. These high-efficiency systems run nearly silent on alternative power, require significantly less fuel, and have a much lower environmental impact. Their performance can be compounded by monitoring them with a remote management solution.

These generators are a fantastic solution for regions where these renewable energy sources are readily available, especially where fuel costs are generally high. In areas where the grid is regularly unstable, these generators can become the primary power source while minimizing fuel use wherever possible. In periods where system load is high, the backup batteries included can be charged by the excess energy output.

Keep your generators in check - What are Generator Controllers?

A generator controller, or generator control panel, is the “brain” of the operation, providing a live display of KPIs and alerts, along with engine control capabilities. These systems are designed to be super durable, including weatherproofing and acoustic reduction, and can even be a module separate from the actual generator.

Generator control panels often include buttons or turnkeys for engine on/off functions and are responsible beyond controlling the generator, for protecting the generator as well. Generator control modules also ensure that metric readings don’t cross your established red lines and alert you when and if it occurs.

Though these systems often provide real-time performance metrics, they are only accessible in person. This means that any potential malfunctions or alerts to performance outliers can be missed until a technician is physically onsite. Depending on the location, this can take days, weeks, or even months.

That is why implementing an Remote monitoring and management (RMM) solution like Galooli’s to monitor and manage your generators and other energy assets is so crucial. Now that you have an eye on your gauges, let’s talk a bit about the importance of effective fuel management.

Watch your fuel gauges - The importance of fuel management for generators

The last thing a site operator needs when site operations get interrupted is a low fuel warning for the onsite generator. Worse still, lacking fuel for extended periods of time can cause additional wear and tear on the generator, forcing unplanned replacements and maintenance.

Fuel issues, whether a product of use or malice, are frequent for remote site operators, and the only way to effectively mitigate that is real-time monitoring. Otherwise, the only way to detect an issue would be to physically arrive at the site, and by then it could be too late.

In certain regions, fuel theft is rampant due to high costs and inconsistent supply. Many sites end up experiencing unintended outages because of this, and require a technician onsite to assess the issue. Generator maintenance is an unfortunate necessity for effective operations of remote sites and facilities.

What if that could all be done from a screen thousands of miles away, and even detect if the fuel issue is maintenance or malicious in nature? This is where an RMM tool with a fuel monitoring system capable of monitoring a variety of energy sources becomes relevant.

Beyond uptime, understanding your generator’s fuel usage is paramount to making operations more efficient and less wasteful. Excessive use could point to a problem that needs dealing with before it becomes more serious and actually affects site stability.

It is also worthwhile to determine if the generator is running only when it needs to as a backup supply. Sometimes with grid instability or misconfiguration generators can run even when sites are idle or under low load, wasting fuel needlessly and requiring more frequent refueling.

So how does Galooli take on the challenge of monitoring and managing generators’ fuel use and improving fuel efficiency?

It’s time to open up visibility for your remote energy assets

Galooli provides generators and practically any energy asset employed onsite real-time monitoring and management capabilities. This goes beyond simple visibility, and puts you in control of your assets. Whether its cutting-through configuration issues or ensuring energy backups are running properly, Galooli’s solution provides an agnostic answer to these issues.

Our platform offers holistic visibility for remote infrastructure whether it is a single generator, multiple energy assets, or even thousands spread across a country. Regardless of your deployment’s scale, Galooli can give you an inside look into each energy asset, or collectively analyze operations relative to other sites.

Through our AI-enhanced analytics, we can provide predictive reporting and alerts to ensure site operators know about issues before they happen. Also, instead of needing to reconfigure and update firmware at each of your sites, why not update and sync everything from a easy-to-use interface?

Whatever generator your site relies on, diesel, or hybrid energy sources, Galooli will provide live monitoring to ensure their operation maintains peak levels. Though generator control modules provide relevant information for technicians onsite, it’s about time those actionable insights are on a screen in front of you.

Connect With Us

operational cost savings & efficiency?